Imagination

in industry

Tomorrow's ideas today

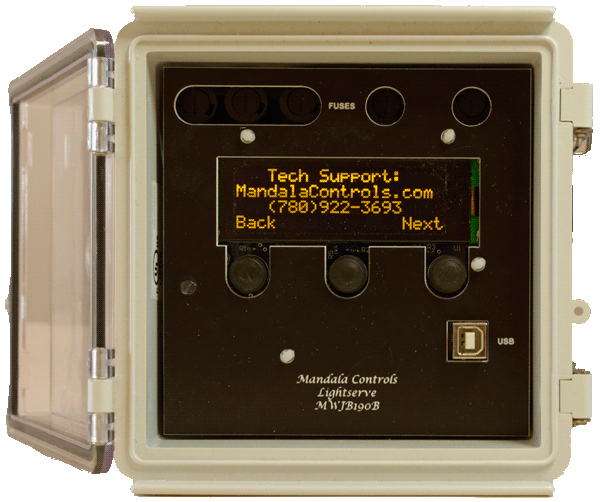

Lighting Controller

MWJB190B

The Mandala Lighting Controller is a modern design, including local display and programming capabilities. The unit performs an astronomical calculation to determine sunrise and sunset times at the plant's location on any particular date.

Timed Bypass

Lights on for 1-2 hours, then off.

Two Main Relay Circuits

Different control logic for Grade Level vs. Upper Level lights. Phased pull-in for inrush control.

Six Extra control circuits

Phased pull-in for low inrush current.

Possibility of different logic on all 6 circuits.

If all 8 circuits control a 3-pole contactor, 24 lighting circuits.

Wide voltage range

85-277 VAC. Tolerant of less stable power supply.

Display

Easy setup. No need for laptop computer in Hazloc.

Non-incendive circuits

Use inexpensive non-classified switches and lights in Zone 2.

(Similar to intrinsic safety, but for Zone 2)

USB Communication

Simple, standard computer interface.

Accurate Clock

5 parts per million, within 0.5 seconds per day

State of the Art

Components more readily available.

Long-term support.

Panel Cost Advantages

Simple logic for 24-circuit lighting panel. Non-classified switches and pilot lights.

Filter Panel

The Zone 2 filter panel allows this technology to be installed in areas where explosive gas might be present. We use fine filtration units manufactured by C. C. Jensen and distributed by Klassen Specialty Hydraulics. We add motor starters and other control devices in our Restricted Breathing enclosure. The finished product operates from 120 volt single-phase power, and is certified for operation in Zone 2 and Class I Division 2 hazardous areas.

Filtration units are used to remove impurities from lubricating oil. They are often applied on large motors operating at high voltage in dirty environments. The goal is to increase the bearing life to at least the interval between major planned shutdowns.anel. Voila!

We offer a spark-safe cord set for hazardous areas. It uses standard twist-lock ends, so it looks and costs more like an ordinary-location cord.

The Spark-Safe cord set is electrically interlocked. There can be no spark, because the receptacle is powered down unless a plug is inserted and locked into place. When the plug is twisted to unlock it, power is disconnected before the plug can be removed.

- 3-Phase 208 VAC to 480 VAC, 15 to 30 A

- Single-Phase 120 VAC to 277 VAC, 15 to 30 A

- Length 25, 50, 75, 100 feet

- Flexible cable, Type SOW or SOOW

- Temperature range: -40 to +60 Degrees C

This protection method is allowed for Zone 2 locations under CSA standard C22.2 No. 60079-15. The protection method is designated “Ex nC”.

SmartCord

Legacy Lighting Controller

MWJB190A

Automate Light Control in Hazardous Locations

Perform an astronomical calculation to determine sunrise and sunset times at the plant's location on the particular date.

Turn the lights on before sunset, and turn them off after sunrise.

Manual Override

Command it to turn on the lights at any time of the day. The lights will remain on until the next sunrise; then return to automatic operation.

Total Time Counter

Log the total time that the lights have been turned on since installation. A Relamp Alarm can be configured to indicate to the operator when the total lamp time has exceeded a setpoint. This allows plant maintenance staff to replace all lamps at the same time, reducing maintenance costs.

Optional Temperature Sensor

Monitor the ambient temperature to ensure that the lamps will light correctly when energized. If the ambient temperature approaches the low temperature limit of the lamps, turn the lamps on to prevent starting problems.